The manufacturing industry has undergone a remarkable transformation from its inception to the present day, shaping economies, societies, and the environment on a global scale. This essay traces the evolution of manufacturing, highlighting key milestones, technological advancements, and statistical data.

Early Beginnings: Craftsmanship to Mechanization

The roots of manufacturing can be traced back to ancient civilizations, where artisans employed rudimentary methods to produce goods. For instance, the production of pottery in Mesopotamia around 3500 BC and the forging of metal tools in Egypt showcased early stages of manufacturing. Historically, these processes required skilled labor to create tailored products, a system often referred to as craft production.

The Industrial Revolution, beginning in the late 18th century, marked a seismic shift in manufacturing practices. This period was characterized by the introduction of machines that significantly improved production efficiency and volume. The advent of the steam engine, coupled with the mechanization of textile production, particularly in Britain, catalyzed unprecedented growth. By 1800, Britain was producing approximately 80% of the world’s cotton textiles, driven by innovations such as the spinning jenny and power loom.

The Rise of Mass Production

The concept of mass production, defined as the manufacture of large quantities of standardized products, emerged in the early 20th century. Pioneered by Henry Ford, the assembly line revolutionized manufacturing in the automotive industry. By 1913, Ford’s Highland Park plant could produce a Model T every 93 minutes, drastically reducing production time and costs. This model facilitated the production of 15 million units by 1927, underscoring the efficiency of mass production systems.

Statistical advancements during this era are noteworthy. In the United States, the manufacturing sector contributed approximately 30% to the GDP in the 1950s, employing around 30% of the total workforce. This dominance of manufacturing continued into the late 20th century, with sectors such as electronics, steel, and automotive driving economic growth.

Globalization and Technological Integration

The latter part of the 20th century witnessed the globalization of manufacturing, influenced by the expansion of trade agreements and technological innovation. The North American Free Trade Agreement (NAFTA), implemented in 1994, exemplified this trend, facilitating cross-border production and supply chain efficiencies. By 2000, about 27% of U.S. manufacturing jobs were tied to exports, illustrating the international interdependence of the sector.

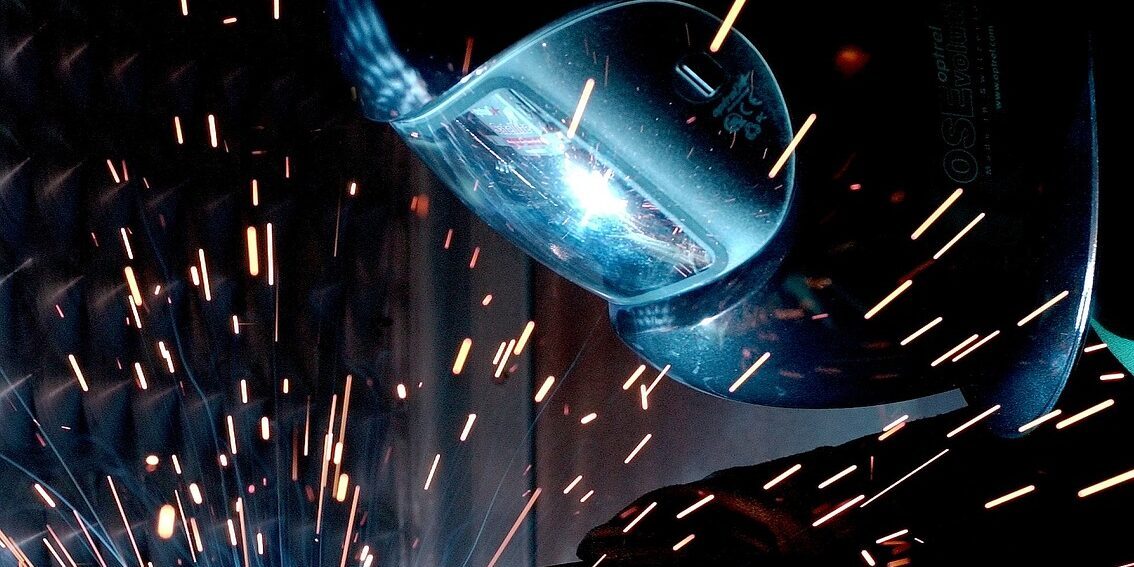

In parallel, information technology and automation emerged, augmenting manufacturing capabilities. The introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems revolutionized product design and production processes. A 2021 report by the World Economic Forum indicated that over 80% of manufacturers were adopting some level of Industry 4.0 technologies, including IoT (Internet of Things), robotics, and artificial intelligence (AI), enhancing productivity and precision in manufacturing.

Current Trends and Future Predictions

As of 2023, the global manufacturing sector is estimated to be valued at approximately $40 trillion, with the U.S. manufacturing industry alone contributing around $2.3 trillion. The sector has shown resilience, rebounding from disruptions caused by the COVID-19 pandemic. Notably, the shift toward sustainable manufacturing practices has gained traction. According to a recent study by McKinsey, 60% of manufacturers are now prioritizing sustainability initiatives, driven by regulatory pressures and consumer demand for responsibly produced goods.

Data from the Bureau of Labor Statistics indicates that while manufacturing employment in the U.S. has declined from its peak in the 1970s, productivity has doubled, illustrating a shift towards higher efficiency and advanced manufacturing techniques. The focus is increasingly on smart manufacturing, emphasizing flexibility, adaptability, and sustainability, aligning with global efforts to mitigate climate impacts.

Conclusion

The history of the manufacturing industry is a testament to human ingenuity, adaptability, and resilience. From early craftsmanship to advanced automated systems, each phase of evolution has brought forth new opportunities and challenges. The sector continues to evolve, embracing technological advancements and sustainability practices that shape its future trajectory. Essential for economic growth, job creation, and innovation, the manufacturing industry remains a cornerstone of global economies, poised to influence the world for decades to come.